Leaking threaded joints are a nuisance that can lead to wasted resources, property damage, and safety hazards. Disassembly for repairs can be time-consuming and costly, but there are ingenious ways to halt leaks without resorting to it.

Image: www.pinterest.com

Identifying and Fixing Leaking Joints

To determine the source of a leak, inspect the joint visually. Look for obvious cracks, gaps, or corrosion. If the leak persists, try tightening the joint with a wrench or pliers. Be cautious not to overtighten, as this can damage the joint.

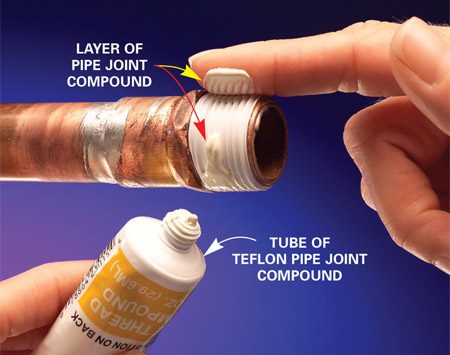

If tightening doesn’t resolve the issue, try applying a sealant specifically designed for threaded connections. Wrap it around the threads and tighten the joint. PTFE tape and pipe sealant are common options that form a temporary seal. Repeat the process if the leak persists.

Alternative Sealing Methods

When traditional methods fail, consider innovative solutions:

- Epoxy: Mix epoxy and apply it generously to the threads. Allow it to set completely before tightening the joint. This method provides a strong, durable seal.

- Hydraulic cement: Create a paste by mixing hydraulic cement with water. Apply it to the threads and tighten the joint. This paste expands when in contact with water, creating an effective seal.

- UV curable adhesives: These adhesives are applied to the threads and exposed to UV light for a fast and strong cure. Ensure the joint is thoroughly dry before applying the adhesive.

Tips for Success

For best results, adhere to the following tips:

- Clean the threads thoroughly before applying any sealant.

- Apply sufficient sealant to ensure a complete seal.

- Allow ample time for adhesives and sealants to cure before pressurizing the joint.

- If the leak persists, consider seeking professional assistance.

Image: www.familyhandyman.com

FAQs on Leaking Threaded Joints

Q: Can I use regular glue to fix a leaking threaded joint?

A: No, regular glue is not suitable for sealing threaded joints. Use sealants specifically designed for this purpose.

Q: How long do I need to wait before pressurizing a joint repaired with epoxy?

A: Refer to the specific epoxy manufacturer’s instructions. Generally, allow at least 24 hours at room temperature for epoxy to fully cure.

Q: Can I apply sealant over an existing leak?

A: It’s best to clean the leak area before applying sealant. Applying sealant over an active leak may not provide an effective seal.

How To Fix Leaking Threaded Joint Without Disassembly

Conclusion

Fixing leaking threaded joints without disassembly is possible with the right techniques and materials. By identifying the source of the leak and applying appropriate sealants or alternative methods, you can stop leaks effectively. Remember to prioritize safety and seek professional assistance when necessary. If this topic has piqued your interest, delve further into the fascinating realm of threaded joint repair and master the art of leak-free connections.